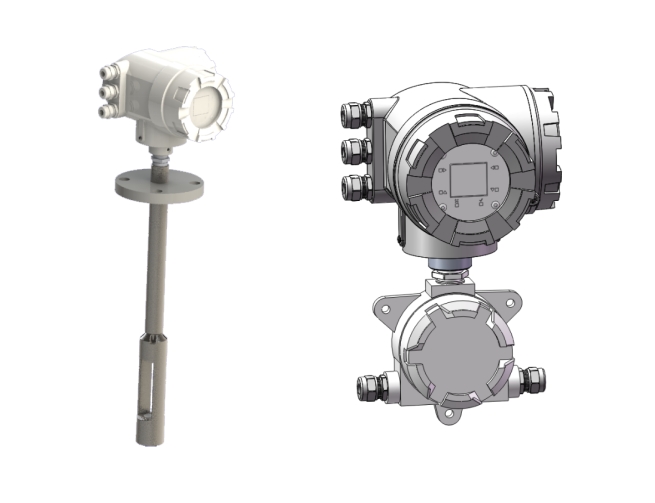

Plugin ultrasonic flowmeter for gas flow measurement. Suitable for measuring the flow of industrial gases with low flow velocity, low pressure, and high dust content. Based on many years of experience and the use of advanced technologies, KEEPSMART AUTOMATION LLC is constantly developing new approaches to solve various practical tasks and technological challenges. A simple and efficient solution for flow control. Cost-effective gas flow measurement at low pressure and high dust content, requiring no maintenance.

Advanced Technologies

1. New Generation of Ultrasonic Measurement Technologies

An improved ultrasonic sensor that effectively overcomes the influence of low pressure, dust, water vapor, etc., while ensuring accurate measurement. It features an automatic sound velocity tracking technology that adaptively adjusts the rate of change of sound. The sensor uses a unique thickness-vibration operating mode, which enables it to measure the flow of both gas and liquid.

2. Unique Electronic Unit Design

A universal device with multi-model and multi-channel sensors, featuring a built-in algorithm for temperature and pressure compensation to measure both volumetric and mass gas flow.

3. Unique Sensor Technology

The pressure sensor can be replaced in real time; adaptive adjustment of gas pressure from 0.7 to 160 bar, and seamless transition from gas to liquid.

4. Easy Installation and Maintenance

Only vertical installation in the pipe opening is required, with no need for tilt angle calculation or precise positioning. A pluggable online module provides a simple, cost-effective, and low-maintenance solution that significantly reduces maintenance costs.

Specifications

1. Easy installation, low cost, and online installation capability.

2. Virtually zero pressure loss and no leakage.

3. Wide measurement range, capable of measuring operating pressure at low and even negative pressure.

4. Fixed beam path, no calibration required.

5. Resistant to high dust levels and adhesion.

6. Probe is corrosion- and wear-resistant.

7. Suitable for use in explosive environments.

Applications

1. Suitable for blast furnace gas, coke oven gas, converter gas, and others.

2. Applicable for compressed air, pipeline air, nitrogen, etc.

3. Including natural gas, fuel gas, acetylene, and more.

4. Exhaust gases, waste gases, methane, and others.

Technical Parametersатчик

Sensor | Transmitter | ||

Nominal SIze (DN) | DN80~DN2500 | Output Signal | 4-20mA |

Mounting Method | Remote Type (Split) | Power Supply | 24VDC |

Number of paths | 1-path | Power Consumption | 15W |

Accuracy | ±2% | Damping Time | 1s |

Repeatability | 0.4% | Response Time | 0.5s |

Flow Velocity Range | 0.03~30m/s | Ambient Temperature | -40~70℃ |

Flange Standard | DN50 ANSI Class150 RF | Protection Grade | IP66 |

Flange Class | 1.6MPa | Enclosure Material | Cast aluminum (epoxy resin) |

Probe Material | Titanium Alloy | Explosion-Proof Certification | Exd IIC T6 |

Protection Grade | IP66 | Self-Diagnosis | Supported |

Medium Temperature | 80℃ / Higher temperatures | Display | 128×64 Dot-Matrix LCD Screen |

available upon request | Menu Language | Chinese / English | |

- PREV:No Data

NEXT:KSAURA-CF2000 Coriolis mass flow meter